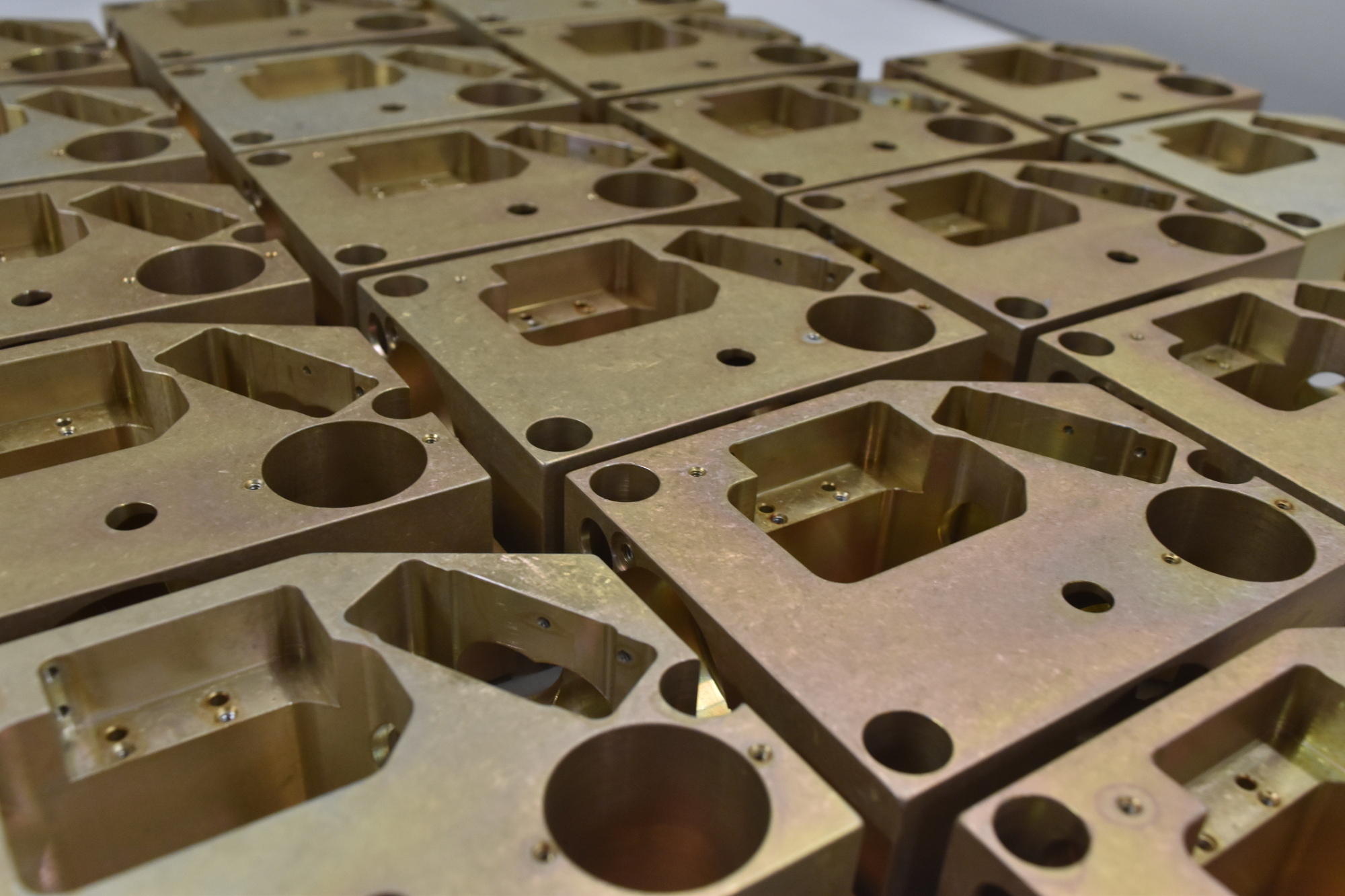

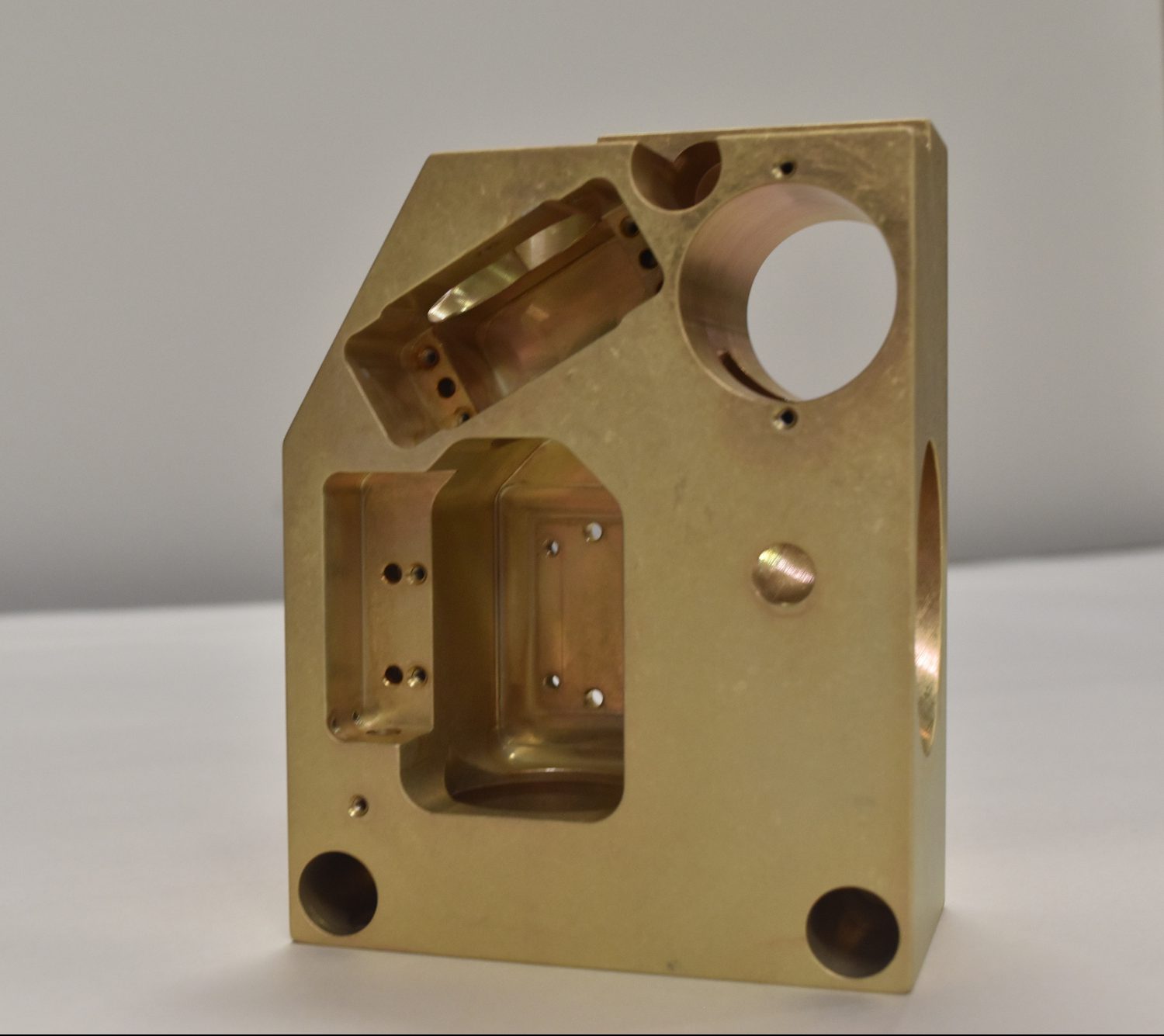

- Dimensions

- 5.5″ x 4.1″ x 2.2″ (inches)

- Services

- In-house Milling

- Gold Iridite (MIL-DTL-5541F, Type 2, Class 1A; RoHS)

- Tightest Tolerance

- ±0.0005″ dimensional

- ±0.001″ flatness

- ±0.002″ parallelism

- Customer

- Located in Danbury, CT

Working with one of our customers in the optical industry, Jurman Metrics Inc. used our CNC vertical milling capabilities to machine this frame, constructed from 6061 aluminum. This piece is integral in its spectroscopy application, as it is used for light sourcing and detection. Working on our SuperMax 3 Vertical Machining Center, we carried out a number of CNC milling operations to achieve the proper dimensions, specifications and features for the frame: a mill profile process, milled windows, reaming, counter-boring, drilled holes, boring and threading and tapping.

Our facility is able to achieve tolerances as tight as ±0.0005″, and for certain features different tolerances were required, for instance flatness to ±0.001″ and parallelism to ±0.002″. Once the vertical milling process was completed, a RoHS compliant gold iridite finish was applied to the 6061 aluminum base.